Flight Case

MADE TO MEASURE

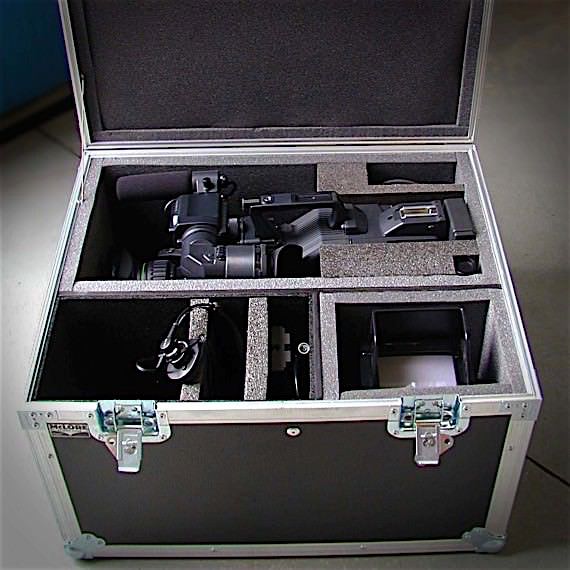

Flight cases mean practicality, orderliness, speed, and safety and organistion when loading/unloading and transporting equipment and goods of all kinds.

Flight cases came into being during the 1960s within the ambit of transport of military equipment. During the late 1990s, many other uses were found for flight cases in various technical, artistic and industrial ambits. Thanks to the process of globalization, the development of air transport and the evolution of materials, flight case use emerged in any number of sectors.

The flight cases are designed to provide appropriate protection for the specific item transported (including goods considered hazardous). They also optimize stowage in various means of transport, ranging from trucks, wagons, containers and aeronautic shelters, (in conformity with the ATA300 standard).

The benefits of flight cases are owing to their parallelepiped form and recessed accessories, such as closures, handles and trays. Flight cases are designed to optimize and to fully exploit cargo areas so that no spaces are left unused. Choice of materials for flight cases strictly depends on their intended use and on the means of transport adopted.

MEANS OF TRANSPORT

If you know the means of transport you’ll be using, you can select the perfect flight case for your needs!

Regulatory compliance ATA guarantees the user the flight case for a period of ten years or two hundred transfers.

MATERIAL

The question of the material to be used is also vitally important. We use and test the best materials to ensure maximum safety and security.

Corrugated aluminium

MaterialiCarbon fibre

MaterialiLaminated fibreglass

MaterialiAstroboard

MaterialiLaminated Kevlar

MaterialiLaminated multilayer phenolic wood

MaterialiSECTOR FOR USE

If you need to take certain items abroad (equipment or objects of any other kind) you know you can rely on our flight cases.

Racing world

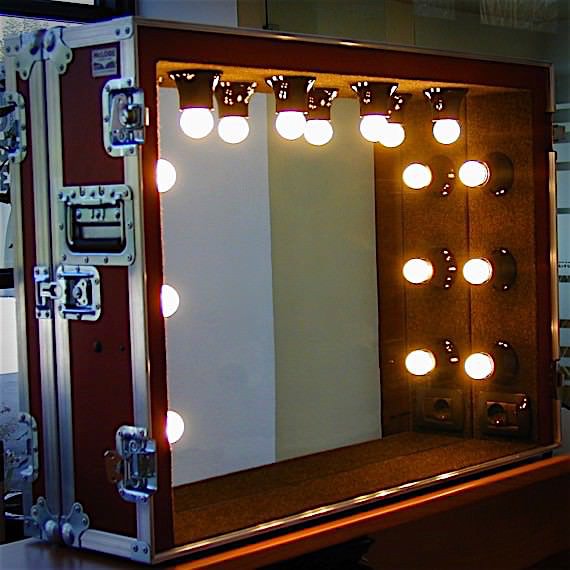

Flight CaseAudio/Video/Rental

Flight CaseLightning

Flight CaseMUSICAL INSTRUMENTS

Flight CaseINSULATED

Flight CaseCatering

Flight CaseHome Design

Flight CaseIndustry

Flight CaseABOUT US

Flight CaseFlight Case Made-to-measure

Flight CaseHorse riding

Flight CaseTHEATRE

Flight Case

DO YOU NEED A MADE-TO-MEASURE FLIGHT CASE?